Modeling intermixed hydrophobic/hydrophilic electrocatalysts

1. Motivation

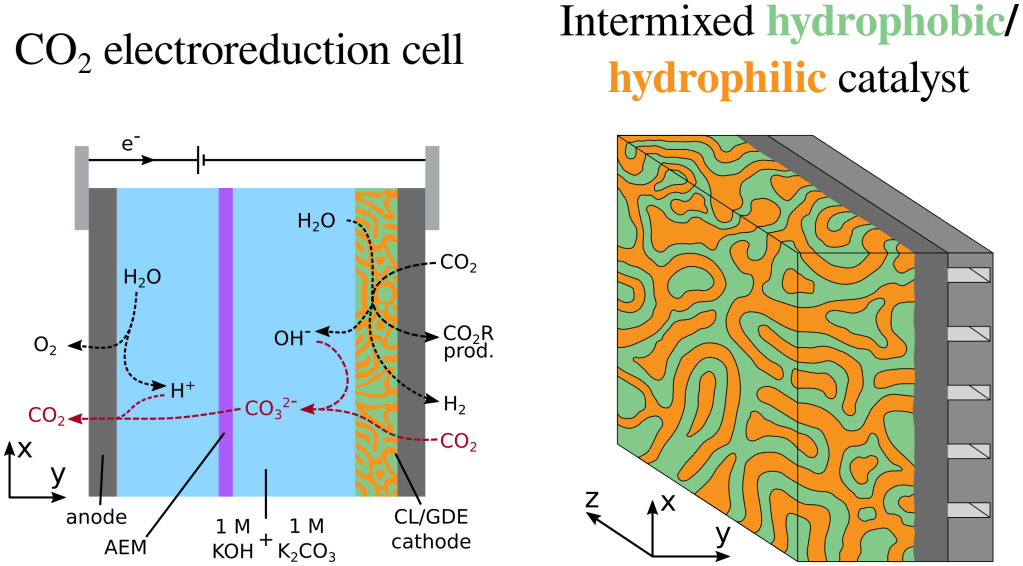

Electrochemical synthesis is a linchpin process in multiple contemporary research endeavors, such as electrification/decarbonization of commodity chemical production [1] and storage/dispatch of renewable energy as chemical fuels [2]. Electroreduction of CO2 offers a pathway toward renewable-powered production of simple hydrocarbons (e.g. ethylene, methanol, formic acid, and other such oxygenates and carboxylic acids). Porous (and hydrophilic) Cu electrocatalysts are known to produce multi–carbon species and exhibit large active surface areas, but recent investigations have shown that the inclusion of sporadically–distributed porous (and hydrophobic) PTFE regions creates additional pathways for the delivery of gaseous reactants, mitigating transport limitations seen in pure Cu catalysts [3–6].

Publications:

Two manuscripts in prep.

Collaborators:

- Stanford Chemistry

- Kyle R. Disselkoen

- Matthew Kanan

As the design space for electrocatalysts has grown to include a wide variety of material and geometric parameters, accurate PDE-based modeling and simulation of such systems has become necessary to understand and optimize the coupled reaction and transport processes that determine cell performance. Here, we develop, numerically simulate, and validate a predictive model that efficiently incorporates a wide range of physical and chemical phenomena in catalyst microenvironments with intermixed hydrophobic and hydrophilic regions.

2. Medium-Fidelity Model

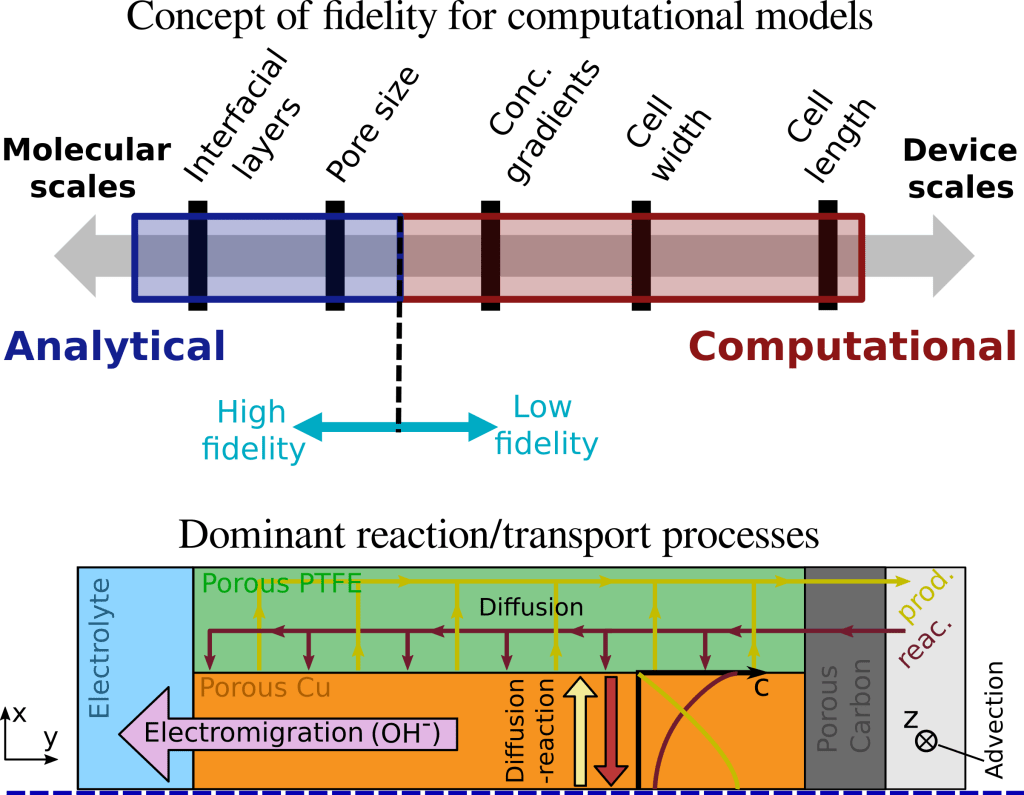

High-fidelity models pose immense computational challenges: Physical and chemical processes occur over a wide variety of spatiotemporal scales, ranging from pore-scale reaction and transport to device-scale gradients in species concentrations. Additionally, the spatial orientation of these features necessitates modeling in multiple dimensions [7, 8], and transport occurs simultaneously through two phases located within randomly-intermixed porous regions. As a result of all these factors, direct numerical simulation using high fidelity models remains prohibitively expensive.

Making use of scaling arguments to identify and preserve dominant physicochemical processes while neglecting higher-order effects, we construct a medium-fidelity continuum model that captures both microenvironment geometric scales and full device scales in 3D.

3. In-house Numerical Solver

The resulting model, coupled with the appropriate numerical methods for treatment of stiff and multi–dimensional problems, permits low–cost exploration of the high–dimensional parameter space associated with novel electrocatalysts, offering quantitative insight into the optimal design of microenvironments for electrosynthesis.

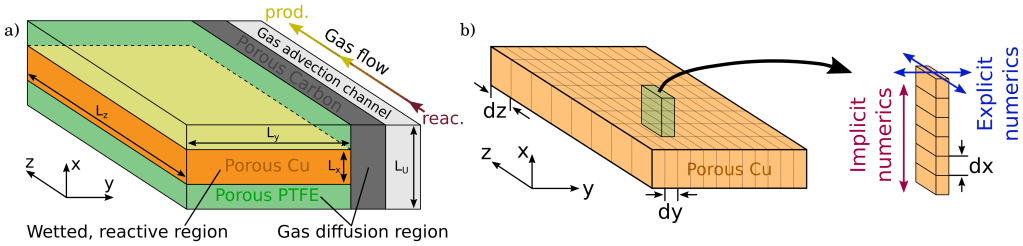

For this problem, we perform a geometric restructuring that retains the dominant physicochemical features while eliminating the elements responsible for computational complexity. The resulting computational domains may be discretized simply using a structured mesh, with iterative coupling between the Cu and PTFE regions. Note, in particular, the selection of implicit numerics in the narrowest dimension, improving numerical stability while enabling parallel decomposition of the domain.

4. Validation Results

Validation results for the cases of both CO2 and CO electro-reduction will be the focus of two upcoming journal articles, slated for submission in early to mid 2025. Results will be summarized on this page shortly thereafter.

References

[1] Schiffer, Z. J.; Manthiram, K. Joule 2017, 1, 10–14.

[2] Yan, Z. et al. Proc. Natl. Acad. Sci. U.S.A. 2020, 117, 12558–12563.

[3] Rabinowitz, J. A. et al. ACS Energy Lett. 2022, 7, 4098–4105.

[4] Wang, Q. et al. J. Power Sources 2015, 279, 1–5.

[5] Xing, Z. et al. ACS Energy Lett. 2021, 6, 1694–1702.

[6] Xing, Z. et al. Nat. commun. 2021, 12, 136.

[7] Kas, R. et al. ACS Sustain. Chem. Eng. 2021, 9, 1286–1296.

[8] Yang, Z. et al. ACS Sustain. Chem. Eng. 2021, 9, 351–361.

Acknowledgements

This work was supported by the Solar Photochemistry and Catalysis Programs of the Chemical Sciences, Geosciences, and Biosciences Division, Office of Basic Energy Sciences, U.S. Department of Energy, under Grant No. DE-SC0021633. Simulations were performed on the Armstrong and Shepard clusters at the Stanford High Performance Computing Center.